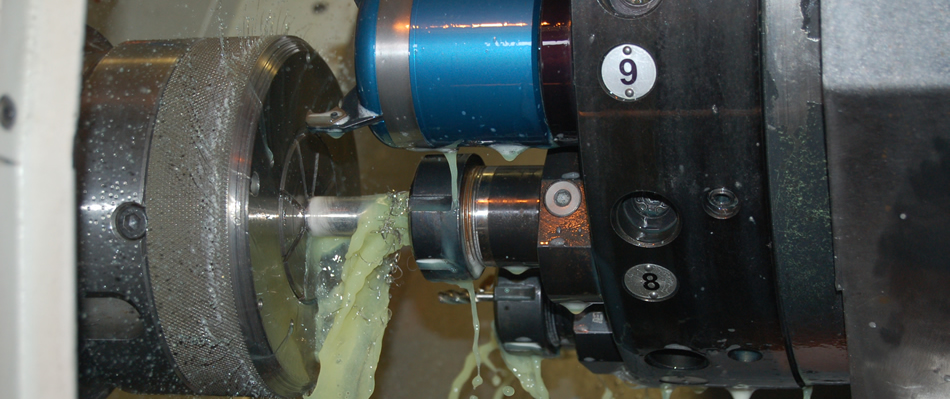

We have dedicated machine shop capabilities which when combined with close working relationships with forgemasters, butt weld fitting and flange stockists allows us to offer full supply of bespoke flanges and fittings, either as a sub contract stand-alone customer requirement or as an integral part of a full supply assembly.

We work comfortably with low alloy through to exotic alloys and enjoy the support of highly skilled and motivated staff. We are committed to continuous investment so that we are able to deliver comprehensive and cost effective machining services and solutions.

CURRENT MACHINING CAPABILITY

XYZ Vulcan 850 VMC with 1000mm x 500mm table Siemens shop mill control boasts repetitive accuracy on drilling, tapping, milling and thread milling.

XYZ Vulcan 150 TC with Siemens Shop-Turn control and multifeed bar feeder which offers up to 46mm diameter barfed, and a maximum turning of diameter of 250mm.

Hardringe Talent 8/52 turning centre with Siemens Shop-turn offer spindle capacity of 52mm. Using a bar puller it can pull from 2mm up to 52mm diameter. Also equipped with live tooling it is capable of milling, drilling, and engraving on both face and diameter of components.

Dugard Lunan 800A VMC with 4th axis Siemens shopmill control – drilling, tapping, milling/thread milling.

Ward 7 big bore lathe up to 17” diameter.

XYZ CT52 LTY Turning centre Siemens shopturn 52mm spindle live tooling.

XYZ 320 LTY Turning centre Siemens shopturn 80mm spindle live tooling.

Herbert No:4 senior capstan lathe with 12″ chuck will turn up to 14″ diameter.

Smart & Brown tool room lathe for small delicate work.

Herbert 6 Pillar drill.

Corona twin spindle drill used for swaging.

Archdale Radial drill.

Bomar Automatic Band Saw with a 300mm diameter cutting capacity.Other machines include Pedestal Drills, Linishers , Polishers and other conventional machinery to assist in ancillary or post machining processes.

Telesis Benchmark 320/470 marking head with rotary chuck.

Quantum 4 CMM measuring machine.

Sensotronic ultrasonics cleaning tank.